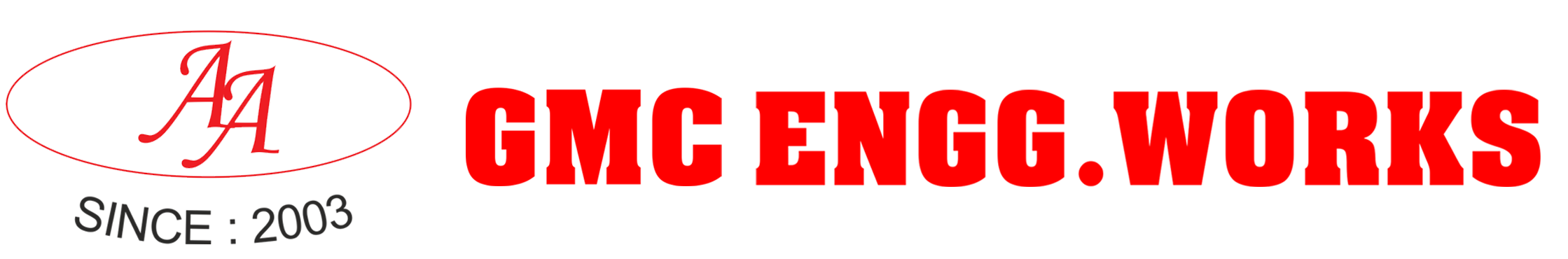

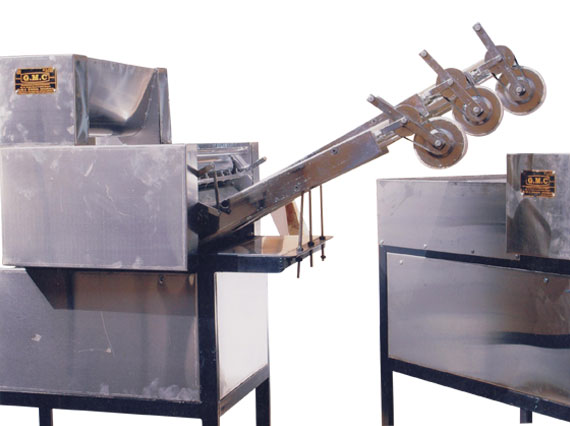

Roller mode, Capacity 2000 per hour

Stainless Steel body and mild steel angle iron frame, Oven comprises of 4 different machines. (Peda) making machine, 2 chapatti rolling machine and chapatti baking oven. Peda making machine is fitted with 1 hp motor, gear box, stainless steel hopper and Oven fitted with 1½ HP motor. Rolling machine is fitted with %½ HP motor, gear box, Compressor 1% HP Moderns 300 ponds Teflon coated conveyors, Brings Imported (URB) from Romania. Belts Imported made in Holland. Stainless Steel roller and dry atta (Flour) sprinklers, Chapati baking and burners blow the stainless steel wire mesh for puffing. Gas supply is fitted with automatic safety valves when the electricity would cut off, Automatically supply of the gas would cut off which controls misshapening (Accident). The oven is fitted with gaze would cut off which indicates the temperature inside the oven. LPG consumption 4%½ kgs per hour approximately, also the weight and thickness of the chapati can be adjusted by Sensors (GMC Own makes),. Size of the chapati can be adjusted from 4" to 6". It is installed in L shape. Machine will be installed in 20X20 feet room.

- 1st Manufacturer Of Chapati Making Machine in India

Benefits Of Fully Automatic Chapatti Making Machine

- Save Manpower (7 times)

- Save Money

- Save the wastage of food

- Hygienic chapattis

- Same/equal size of chapatti

- Save cooking gas (upto 65%)

- Less effect on the room temperature

- Time Saving

Standard Specification As Per Models

| Sr. No | Type of Chapati Making Machine | Gas Usage | Size of Chapati | Size |

| 1 | Fully Automatic Machine (Produces 4500-5000 Chapaties per hours) Power Consumption 5 HP. |

8½ kgs per hours | 4" to 6" | 20 ft. X 20 ft. |

| 2 | Fully Automatic Machine (Produces 3000-3500 Chapaties per hours) Power Consumption 4 HP. |

6½ kgs per hours | 4" to 6" | 15 ft. X 20 ft. |

| 3 | Fully Automatic Machine (Produces 1200-1500 Chapaties per hours) Power Consumption 2.5 HP. |

5 kgs per hours | 4" to 6" | 12 ft. X 15 ft. |

| 4 | NEW MODEL Fully Automatic Machine (Mini) (Produces 800-1000 Chapaties per hours) Power Consumption 2 HP. |

4½ kgs per hours | 4" to 6" | 8 ft. X 10 ft. |

Automatic Chapati Making Machine

Working

Switch the baking oven on. The conveyor will start moving. Light up the LPG burners. Let the oven get heated for 10-12 minutes. Put kneaded dough into the hopper of the peda making machines and dry atta into both the hoppers of the sprinklers of chapati rolling machines, which will continuously keep sprinkling on the conveyor to avoid sticking of atta on the conveyor of the rollers. Dough ball (Peda) will fall on the conveyer of the first rolling machines, which will carry the dough ball into the rollers, Flattening into oval shape. The oval piece will then fall automatically on the other side making it round. The round piece will then fall on the conveyor of the baking oven and baked and puffed chapaties will fall out automatically.